Three Phase Motors, Single Phase Motors, Helical Gear Motors, Brake Motors, Torque Motors, Custom built Motors, Bench Grinder, Cooling Tower Motors

Crane Duty Motors, Worm Gear Motors, Oil Submersible Motors, Gear Brake Motors, Clutch Brake Gear Motors, PMDC Gear Motors and Coolant Pumps

Three-phase motors are a type of AC motor that is a specific example of a polyphase motor. These motors can be either an induction motor (also called an asynchronous motor) or a synchronous motor. The motors consist of three main components – the stator, the rotor, and the enclosure.

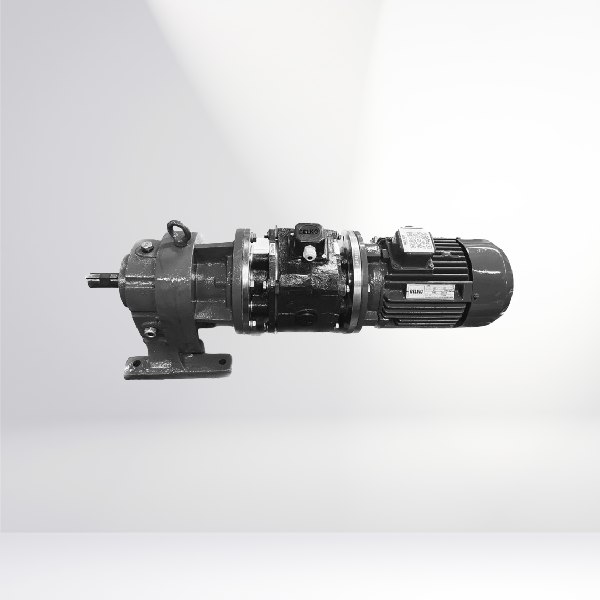

These type of gear motors use helical gears to transfer torque and reduce speed of an electric motor. These gear motors result in high torque and low speed output.

Brake motors are designed to ensure safety due to the braking torque always being applied by means of pressure springs when no voltage is applied to the motor. By applying voltage the armature plate is pulled towards the electromagnet thus loading the pressure springs and allowing the motor shaft to rotate freely . When the current is stopped the pressure springs push the armature plate towards the disc which in turn is pressed against the motor cover and thus braking the motor shaft.

Torque motors are similar to standard motors but have modified high resistance rotor design . The torque of these motors is standard at starting and it has almost linear torque speed characteristics with zero torque at synchronous speed. These motors are used in many applications ie Roller table motors , high speed tapping machines, winding of plastic films, rolls, strips, aluminium, copper, brass, steel wire strips, paper rools etc . Available in various mountings

Made of sheet metal body with precision gauges . Available in TEFC (Totally Enclosed Fan Cooled) & SPDP (Screen Protected Drip Proof)

Motors manufactured according to the customer’s needs and specifications. We manufacture a number of motors for OEMs according to their specifications and application. Voltage and frequency can be altered according to requirement. Shaft & exterior mounting can be designed as per requirement. Therefore your needs our concern.

Our bench grinders are made of High grade quality C.I Casting , with the finest quality stamping and aluminium die cast rotors. Dynamically balanced rotors and shafts ensure quiet and vibration free operation.

These Totally Enclosed Naturally Cooled Motors are used in the refrigeration industry. These Motors have a special long shaft construction with extended threaded end to directly mount the fan. They are available as standard design or can be custom built according to specific drawings.

Suitable for Hoist and Crane applications, these motors have high pull out torque and low rotor inertia. These motors are ideally suitable for intermittent duties.

Construction :- Standards motors are designed for foot mounting (B3). Motors up to frame 280 are also available in B5 mounting.

Highly efficient light weight gear motors. These worm gear motors are made in different specifications and can be customized as per requirement. Flexibility is given by the wide choice of several mounting options, shaft configurations and motor interface, all offered as standard. Worm shaft is made of high tensile case hardened alloy steel which is finished precisely. Worm wheel is made from centrifugal cast phosphererous bronze material.

Highly efficient light weight Oil Submersible Motors. Used in Hydraulic power packs and other industrial / residential projects. These hollow shaft motors are used in lifts, power packs, stack parking etc

Gear Brake Motors are used in industrial applications where precise control of speed and position is required. The gearbox reduces motor speeds enabling it to generate high torque at low speeds. Brake provides quick and reliable stopping power.

Clutch Brake Gear Motors incorporate both clutch and brake mechanisms in a single unit. This combination offers precise control and reliable stopping power. The clutch mechanism keeps the motor running and stops gear box when required giving great control and accuracy in operation.

Permanent Magnet Direct Current (PMDC) Motors use permanent magnets to generate a magnetic field in the rotor. PMDC Motors operate on Diretc Current (DC) and are used in applications where control over speed and torque is required. They can be controlled through analogue or digital signals and PLCs.

Coolant Pumps are used for re circulation of coolant/oil in industries. They play an integral part in grinding and cutting machines. They are used in lathe machines, cutting machines, and various other industrial applications.

We are happy to help you. You may call on phone, WhatsApp or post your enquiry on our email

Indian Electrical Industries is an ISO 9001:2015 certified Company

We are happy to help you. You may call on phone, WhatsApp or post your enquiry on our email

© 2023 Created by Dot Com Designers